Sustainability

We are one of the nation’s leaders in environmental sustainability

For some years now, SP has been on a continuous “update & upgrade” sustainability pathway.

Integrated supply chains

between farmers and consumers

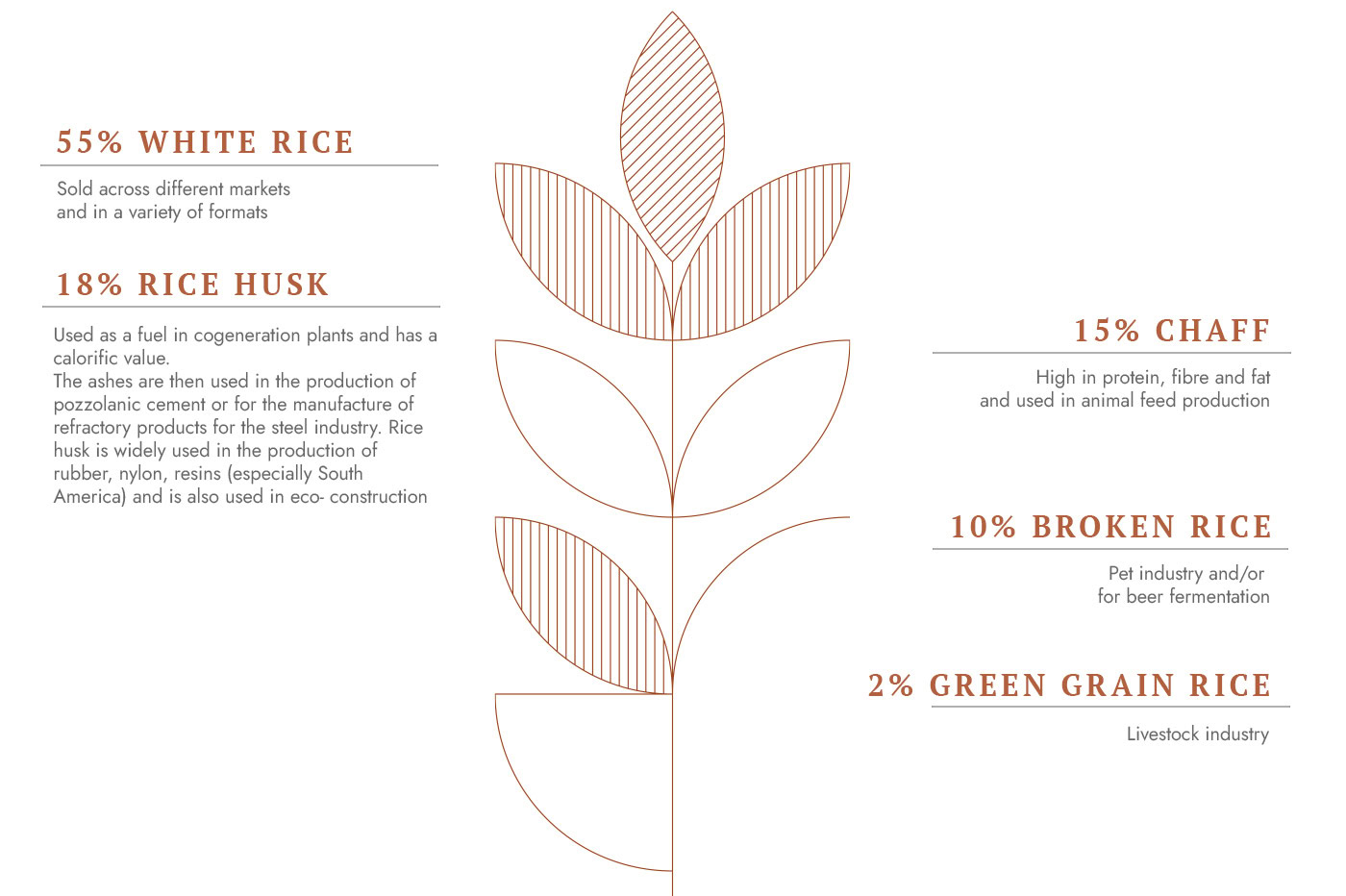

100% product "reused"

nothing is “wasted” but everything is sold, reused and improved

Solar panels

supporting part of the production process

Packaging

new, more environmentally sustainable ideas

Rice processing is 100% sustainable, i.e. there is no waste and everything is reused in the food, livestock, energy and construction industries.

Action plan

We seek and aim to be sustainable across all the various production stages: cultivation, processing, packaging and distribution.

Cultivation

- Cultivation techniques

- Integrated supply chains

- Co-sharing R&D approach for new seeds

Processing

- Monitoring of emissions

- Self-generated energy

Packaging

- New environmentally sustainable and more differentiated packaging

- Attentive regarding environmental ethics

- Waste reduction

Distribution to the customer

- Partnerships with customers

- Good communication of the work carried out and actions taken

A new rice culture

With the new SP Riseria Italian production lines, and in conjunction with local partners (industrial players and master craftsmen, artisans in their field) a new pathway to sustainability was launched to support the cultivation and culture of local rice, but not solely agricultural rice. A new approach to rice cultivation that is no longer focusing solely on the commercial proposition of rice as a simple cooking commodity, but rather on rice as something which, thanks to its organoleptic properties, is also the ideal base for vinegar, beer, and spirits, not forgetting rice oil, rich in Omega 3.